The Multifunctionality of Ambition S Series Zinc Sulfide by Hongzhi New Materials

Mar 29, 2024|

Mar 29, 2024| View:286

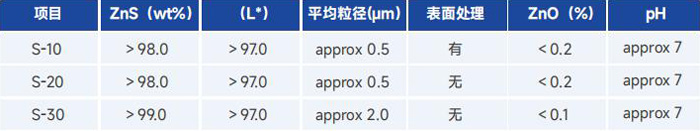

View:286Ambition s Series Zinc Sulfide products by Yunfu Hongzhi New Materials Co., Ltd. are among the few professional manufacturers worldwide with high-quality pigment-grade zinc sulfide production technology, following Germany's SACHTLEBEN company. The performance of these products is comparable to or even superior to foreign competitors, enabling domestic substitution and independent control.

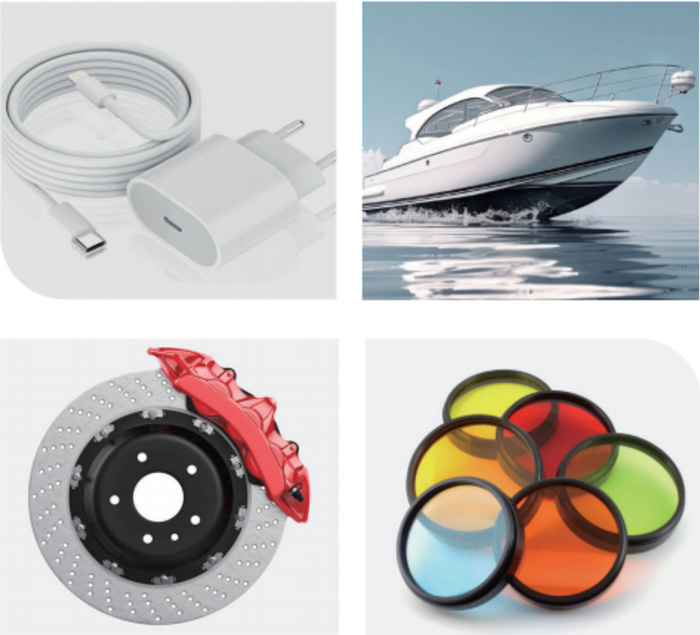

Ambition S Series zinc sulfide is a multifunctional white pigment that imparts unique qualities and advantages to special plastic products and coatings that other white pigments cannot provide. It has demonstrated unique capabilities in various fields such as plastics, rubber, brake pads, chemical fibers, and UV coatings.

Zinc Sulfide, with a refractive index of 2.37 and a Mohs hardness of 3.0, is an important white pigment second only to titanium dioxide (TiO2). During processing, it does not damage glass fibers like titanium dioxide, preserving the reinforcing effect of the fibers. With its surface subjected to organic modification treatment, concentrated particle size, and near-spherical shape, Ambition S series zinc sulfide exhibits excellent rheological and dispersing properties even at high addition levels. This makes it highly suitable as an inorganic lubricant for friction materials while avoiding the embrittlement of elastoplastics. In applications such as brake pads, Ambition S series zinc sulfide offers improved performance and environmental friendliness.

Unlike TiO2, Ambition S Series Zinc Sulfide does not possess photocatalytic properties. It can anchor metal ions with catalytic effects, preventing these ions from entering the polymer lattice and causing catalytic degradation, thus enhancing the weather resistance of plastics.

Ambition S series zinc sulfide also exhibits good thermal conductivity, enabling coating systems to maintain temperature consistency and prevent cracking. In UV-curable coating systems with white pigment, its low UV absorption allows more UV light to penetrate the coating, reducing curing time, improving efficiency, and lowering costs.

As a metal sulfide material, Ambition S Series Zinc Sulfide finds application primarily as a solid lubricant in grease products. It demonstrates excellent lubrication performance, particularly under harsh conditions of high temperature, high pressure, low speed, and heavy load, enhancing the load-carrying, anti-wear, and anti-friction properties of grease.

The following are key points regarding the application of Ambition S Series Zinc Sulfide in grease products:

1. Solid lubricant additive: Ambition S Series Zinc Sulfide can be added to grease as a solid lubricant additive to improve its performance under extreme conditions. It effectively reduces direct metal-to-metal contact, thereby reducing wear and friction.

2. Extreme pressure (EP) performance: Ambition S Series Zinc Sulfide enhances the EP performance of grease, allowing it to maintain lubrication effectiveness under high load conditions and prevent surface damage and adhesion of metals.

3. Anti-wear performance: The addition of Ambition S Series Zinc Sulfide significantly improves the anti-wear performance of grease, reducing wear during mechanical motion and extending the service life of machinery.

4. High-temperature stability: Ambition S Series Zinc Sulfide exhibits excellent thermal stability, maintaining its lubricating properties in high-temperature environments, making it suitable for machinery operating at elevated temperatures.

5. Environmental friendliness: Compared to certain heavy metal lubricants, Ambition S Series Zinc Sulfide is an environmentally friendly lubricant additive that helps reduce environmental impact.

6. Cost-effectiveness: Ambition S Series Zinc Sulfide is a relatively low-cost solid lubricant, offering an economically viable solution to enhance the performance of grease products.

Further research indicates that zinc sulfide as a solid lubricant additive demonstrates improved load-carrying capacity and EP performance of base oils, while exhibiting excellent anti-wear properties.

More research data shows:

According to related studies on the tribological performance of zinc sulfide and its derivatives as solid lubricants, zinc sulfide can effectively enhance the load-carrying capacity and extreme pressure performance of base oils, while demonstrating excellent anti-wear properties.

Related research also indicates that zinc sulfide undergoes frictional chemical reactions with the surface of steel balls, forming a frictional chemical reaction film that protects the friction pair and reduces wear.

In summary, the application of zinc sulfide in grease products primarily leverages its characteristics as a solid lubricant to enhance the performance of grease under harsh conditions, including load-carrying capacity, anti-wear properties, and EP performance. It also offers environmental friendliness and cost-effectiveness advantages.

Language

Language